HOSMAC, Asia’s leading healthcare consultancy was responsible for design project management and equipment consulting for all these Covid Hospital by Vedanta. Additionally the facility management supervision will be done by HOSMAC as well, for a period of six month in order to ensure that all engineering elements are working as per design specifications.

Challenges

Given the restrictions levied across the country due to Covid-19, there were quite a few challenges faced in order to complete the project. One of the major challenges was the mobilization of labour and availability of material resources. Most of the labour in the constructions industry are migrants who moved back to their hometowns and villages during the lockdown. Hence it was difficult to mobilize the needed labours for the setup of the hospital.

Procuring the material posed a problem too since the ones used to set-up these hospitals are not readily and easily available in India, especially during these times. The local residents posed a threat to the set-up of these much-needed hospitals. Since they were to be located in residential areas. They resisted development of a Covid infrastructure so close in their homes, triggered by the fear of the deadly virus. Nature also added to the difficulties, due to heavy rains and storms, a flood like situation hindered the construction process.

Structural Features

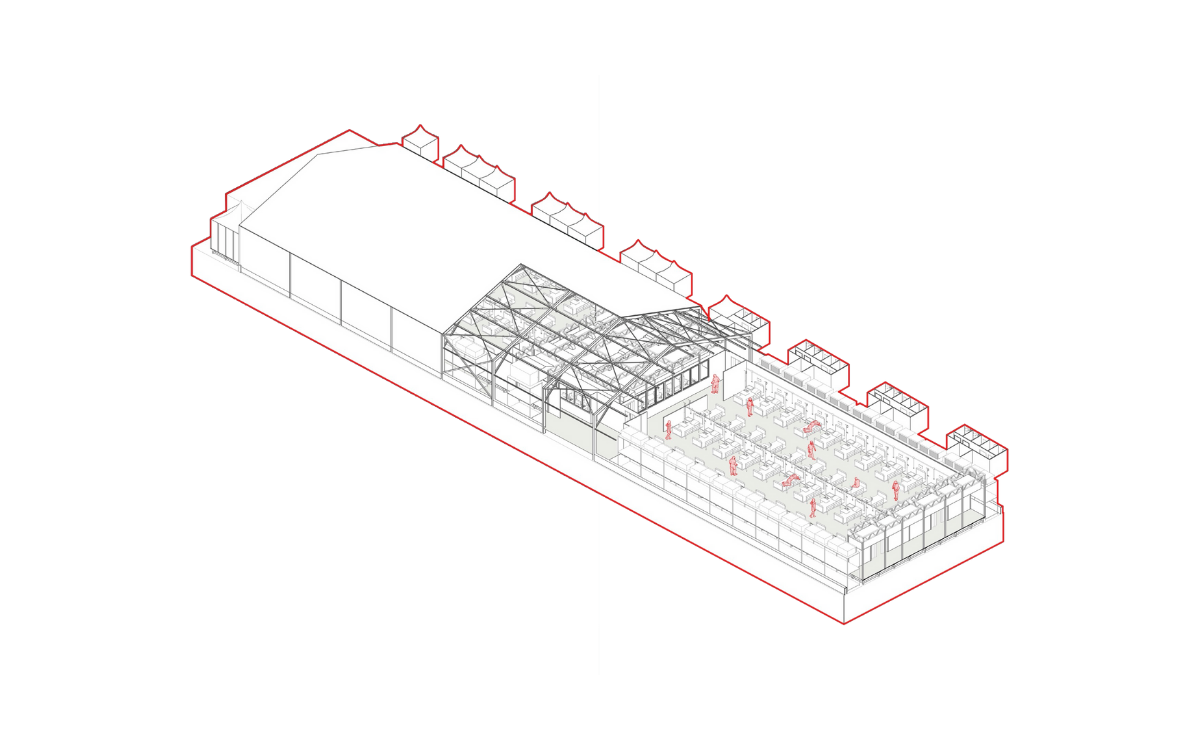

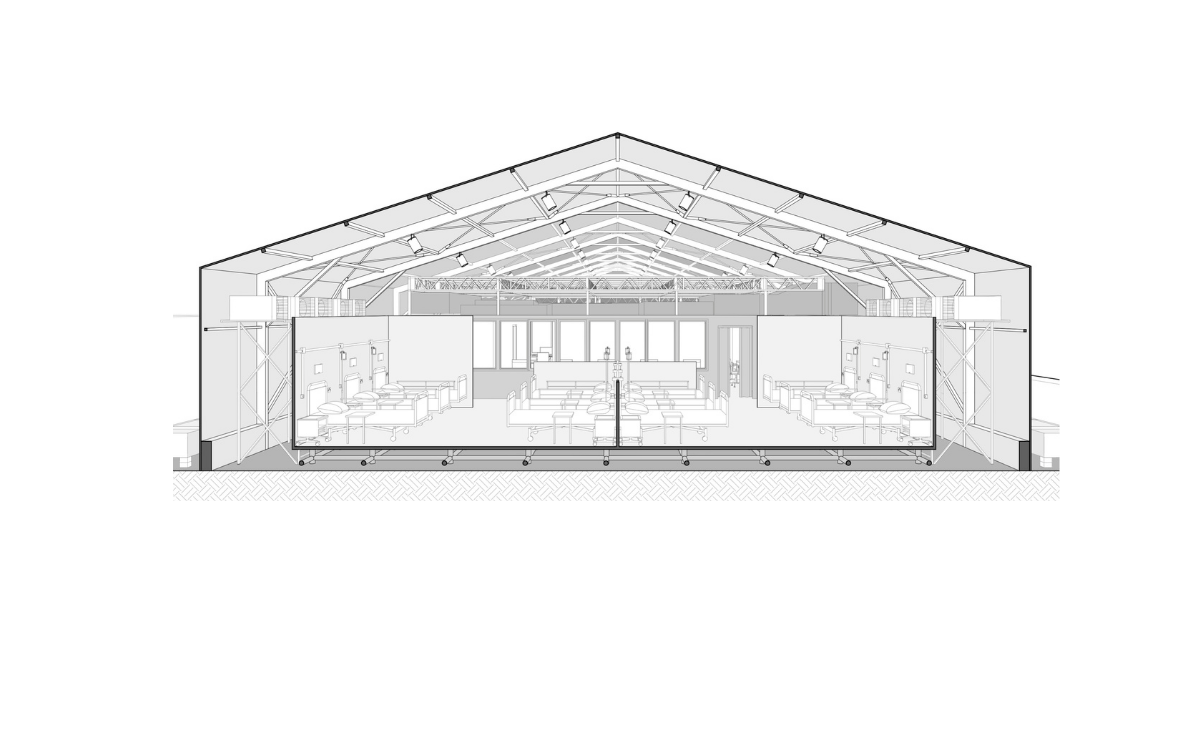

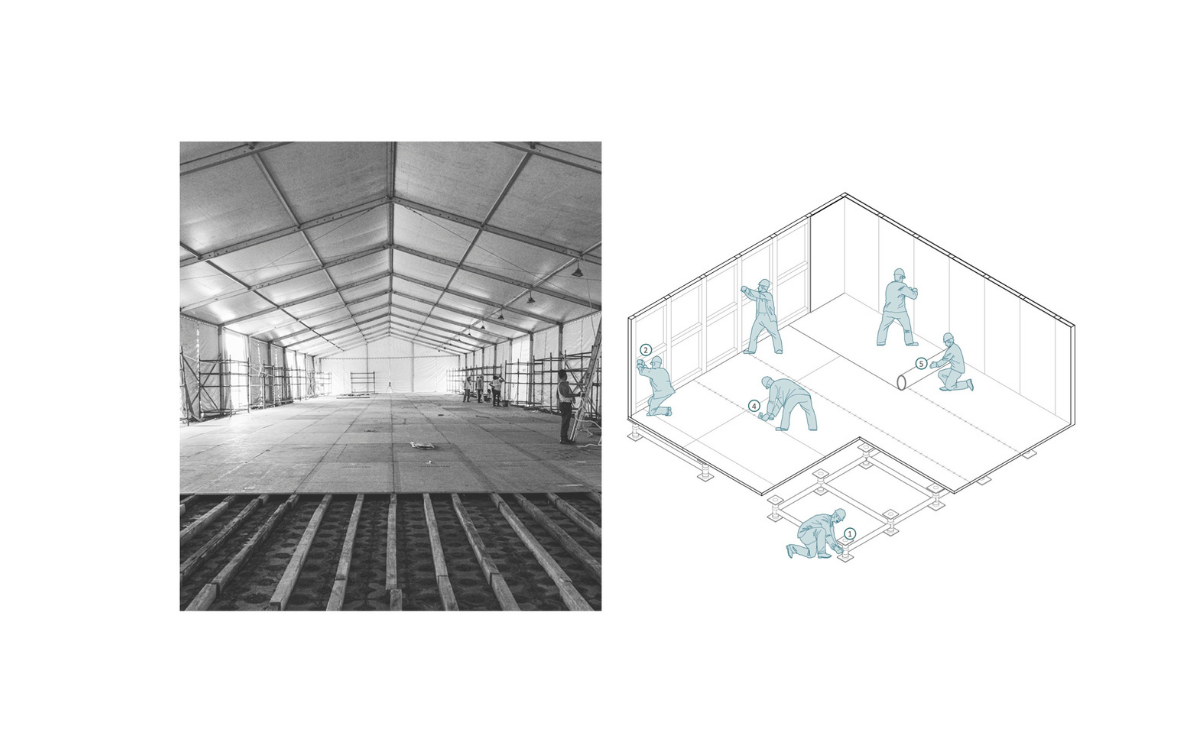

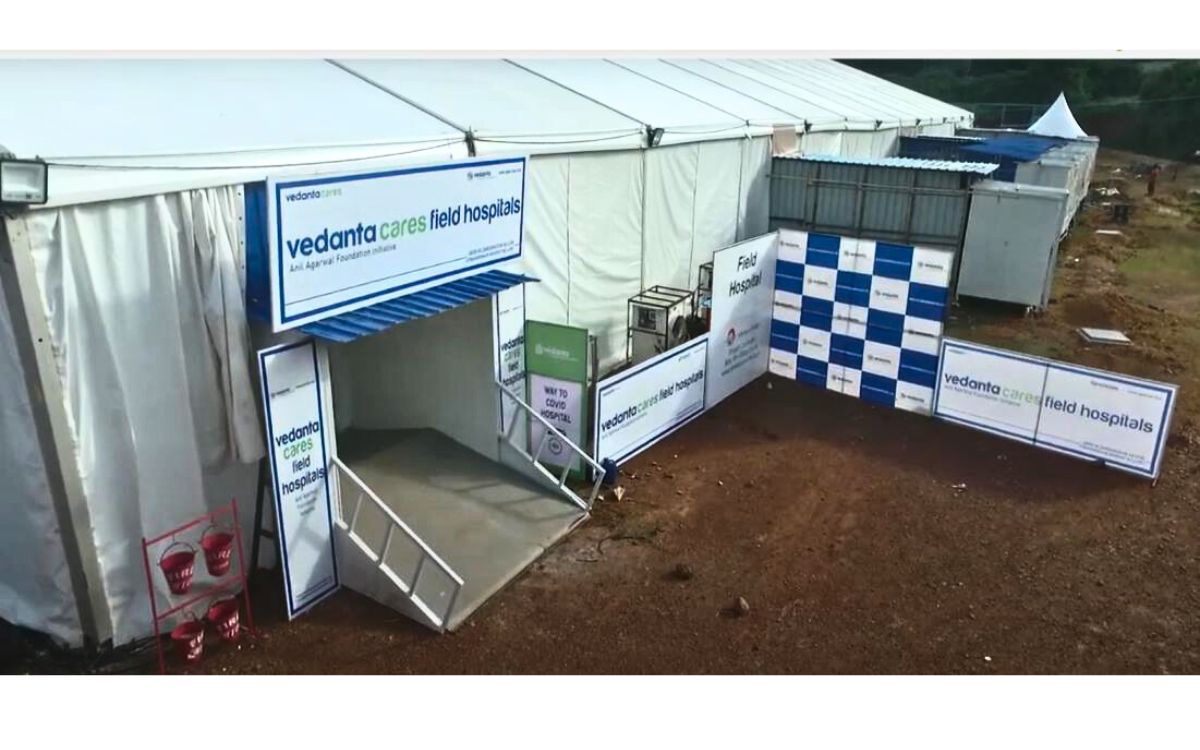

The key aspect of the entire structure is its flexibility. Each of the hospitals has been built using German hangar tents which has been covered with Ferrari fabric. German hangars are light weight and cab be erected within a day or two’s time. The Ferrari fabric is fire and water resistant thereby ensuring safety of the facility. They can withstand win up a speed of 100 km per hour.

Elevated plinth has been made with Modular Iron baton and Iron Frames Structure. All the walls have been erected in terms of modular partitions and Vinyl flooring has been used to make it joint-free and very fast in laying. Each of these facilities on an average is setup on over 23000 Sq. Ft built-tent structure on a plot area of approximately 50 meters by 90 meters.

Medical Specifications

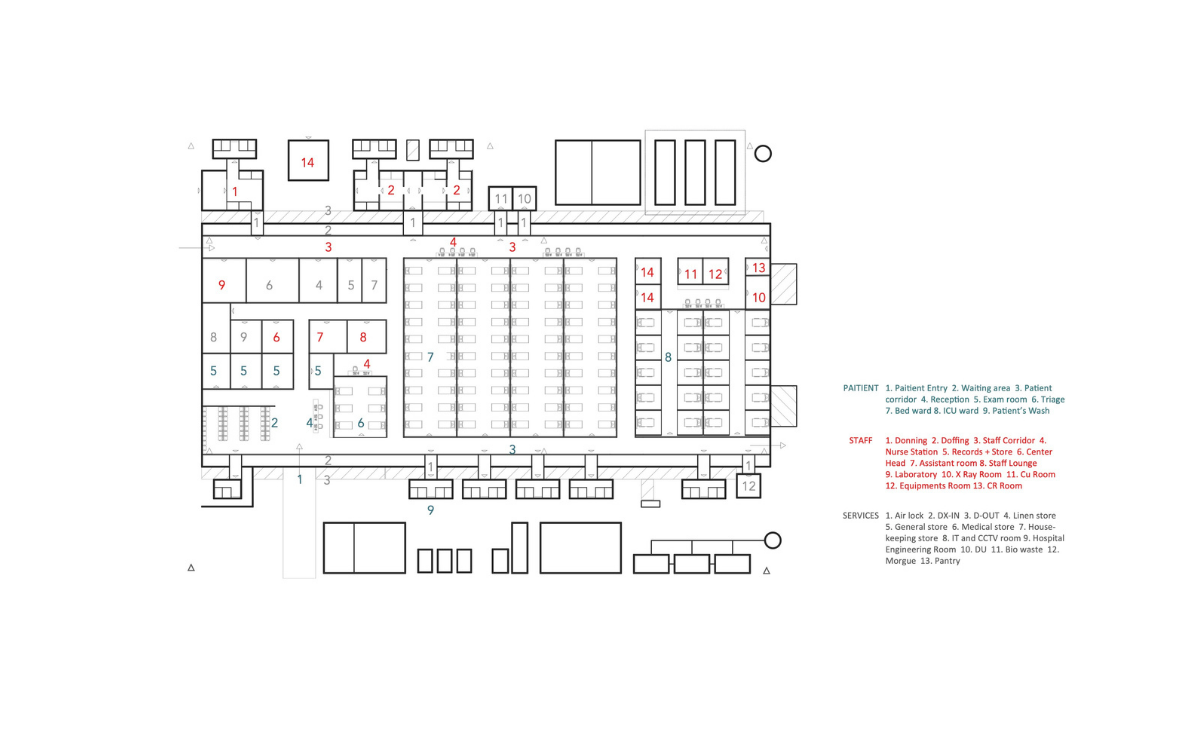

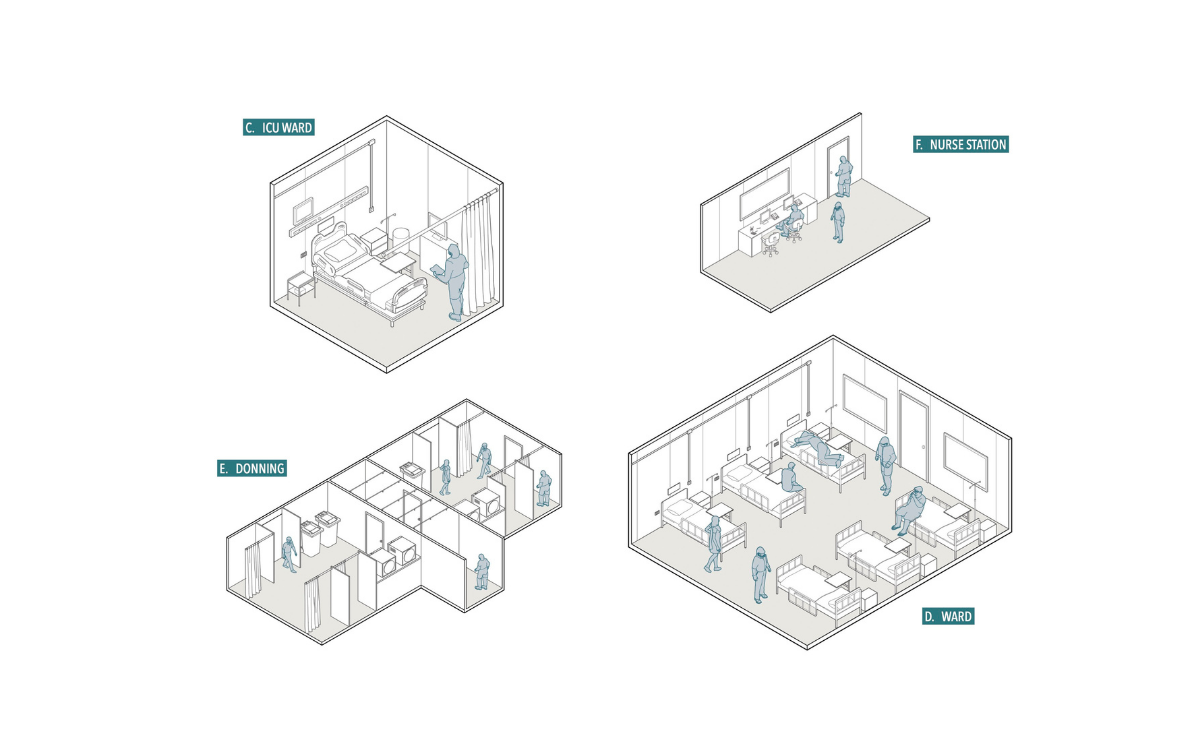

The overall designing has been done keeping in mind all the Covid care protocols. 100 % air conditioning with negative pressure has been provided in the ICU’s of these hospitals. A 3-stage filtration along with UVGI lights has also been installed in exhaust ducts in order to ensure that the air which goes out of the Covid facility is Covid Virus free. All the Facilities have centralized medical gas pipeline system connecting 80 oxygenated beds, 10 HDU beds and 10 ICU beds.

There is a dosing system for neutralization of sewage before it is discharged in the municipal sewage to ensure that the Covid virus is killed in the sewage coming out of the facility. A separate donning and doffing area have been provided for putting on and removing of PPE suit. The Nurse station has central monitoring system with has a direct control of monitors of all the beds in the ICU. The fire exits have been made as per the fire norms and there is 24 hours dedicated fire tanker has been provided to each facility.

Timeline

Setting up 10 Nos. 100-Bed Covid facility across varied location like Dariba & Barmer in Rajasthan, Raipur in Chhattisgarh, Bolcaro in Jharkhand, Kalahandi & Deoghar in Odhisa, Chitradurg & Dharwad in Karnataka, Tuticorin in Tamilnadu and lastly Gurgaon in Haryana was a big resource mobilization and logistic challenge.

Only 20-30 day were given to complete the entire project, right from designing to final execution, commissioning, and handing over the facilities for patient admissions. In fact the Gurgaon facility was handed over for patient admission in 15 days. Time.